Paraffin: Ancient Art and Infinite Variety **Paraffin** is a versatile substance with a wide range of applications. It refers to a group of saturated hydrocarbons (alkanes) that exist in various forms (solid and liquid) and are derived primarily from petroleum or, in some cases, other sources. This material holds a special place in numerous industries due to its unique properties and infinite variety. This comprehensive guide will explore what **paraffin** is, its rich history, diverse types, production methods, and countless uses. 1. What is Paraffin? Definition and Properties **Paraffin** is primarily composed of hydrocarbon molecular chains containing carbon and hydrogen atoms. Depending on the length of these chains, **paraffin** can exist as a liquid or a solid: Paraffin Wax / Solid Paraffin: The solid form of **paraffin**, which is white, odorless, tasteless, and waxy at room temperature. Its melting point usually ranges from 47 to 64 degrees Celsius. It’s composed of longer-chain alkanes (approximately C20 to C40). It is hydrophobic (repels water) and insoluble in water. It’s a good electrical insulator. It is relatively chemically inert. Liquid Paraffin / Mineral Oil: The liquid form of **paraffin**, which is colorless, odorless, tasteless, and transparent. It’s composed of shorter-chain alkanes than solid **paraffin** (approximately C15 to C40). Available in “industrial” and highly purified “pharmaceutical/food-grade” forms. 2. History and Origin of Paraffin: A Journey Through Time The discovery and development of **paraffin** marked a significant turning point in various industries, especially in candle-making and the petroleum industry. Discovery and Naming (Early 19th Century): Karl von Reichenbach: A German chemist, formally discovered and identified **paraffin** wax in 1830. He obtained this substance while studying residues from the distillation of wood tar. Origin of the name “Paraffin”: Reichenbach chose the name “**paraffin**” from two Latin words: “parum,” meaning “little,” and “affinis,” meaning “affinity” or “inclination” (implying “lack of affinity”). This name was selected due to the substance’s high non-reactivity with other chemicals, which is one of its key properties. Commercial Development and Early Applications (Second Half of the 19th Century): James Young: A Scottish chemist, played a crucial role in the commercialization of **paraffin** production. In the 1850s, he developed processes for extracting **paraffin** (both liquid and solid) from coal and oil shales, producing it commercially. He even became known as “Young’s **Paraffin**” due to his work in this field. Revolution in Candle-making: Before **paraffin**’s discovery, candles were primarily made from animal fat (tallow) or beeswax, which produced a lot of smoke and were expensive. **Paraffin** wax revolutionized this industry because: Cleaner and More Uniform Burn: **Paraffin** candles produced less smoke and had a more stable flame. Lower Production Cost: With the development of petroleum refining methods, **paraffin** production became cheaper than beeswax and animal fat, making candles more accessible to the general public. Other Early Uses: In its early days, **paraffin** wax was also used in other industries, including as an insulator for telegraph cables, a waterproofing coating for surfaces, and in match production. Industrial Growth and Diverse Applications (20th Century Onwards): With the growth of the petroleum and meatpacking industries (which produced **paraffin** and stearic acid as by-products), **paraffin** production peaked in the early 20th century. Advances in refining processes (like vacuum distillation and hydrocracking) improved the quality of **paraffin**, paving the way for its diverse applications in cosmetics, pharmaceuticals, food, and other industries. Today, **paraffin** has become one of the most widely used materials globally, maintaining its position due to its desirable properties and cost-effectiveness. For more historical details, you can visit Wikipedia – Paraffin Wax. 3. Main Types of Paraffin: Beyond the Basics Besides the two main forms (solid and liquid), there are other significant types of paraffin or related materials, each with distinct characteristics and applications: Paraffin Wax: The solid **paraffin** described above. Liquid Paraffin / Mineral Oil: The liquid **paraffin** described above. Microcrystalline Wax: A type of petroleum derivative similar to **paraffin** wax, but with a smaller and more irregular crystal structure. It has a higher melting point (around 60 to 93 degrees Celsius) and greater flexibility. Often used in combination with **paraffin** wax to increase hardness and melting point. Chlorinated Paraffin: Liquid or solid **paraffin** combined with chlorine. Used to increase flame resistance (flame retardant) and as a plasticizer in specific industries. Petroleum Jelly / Vaseline: A mixture of liquid **paraffin** and microcrystalline wax with some heavier hydrocarbons. It’s a semi-solid gel primarily used in health and beauty products. 4. Paraffin Production Method: How Paraffin is Made Most commercial **paraffin** is derived from crude oil: Crude Oil Distillation: Crude oil is heated in refineries and separated into different petroleum fractions based on their boiling points. Wax Extraction: Heavier petroleum fractions containing paraffinic hydrocarbons (usually from the “lubricating oil” section) are separated. Dewaxing: In this step, oil is separated from the wax. This can be done by cooling the mixture to crystallize the wax, followed by filtration, or by using specific solvents. Refining: The crude wax obtained may contain impurities, color, and odor. To produce purer grades (especially food-grade or pharmaceutical-grade), refining processes such as hydrogenation (reaction with hydrogen), treatment with activated clay, or activated carbon are used to remove unwanted compounds. Other Methods: **Paraffin** can also be produced synthetically from natural gas (Fischer-Tropsch process) or from coal and oil shale, but production from crude oil remains the most common and economical method. 5. Uses of Paraffin: Household and Industrial Applications Due to its chemical and physical properties, **paraffin** is used in a wide range of products and processes: a) Uses of Paraffin Wax (Solid): Candle Making: The most common use of **paraffin** wax, due to its suitable melting point, clean burn, and ability to hold fragrance and color. Crayons: As a primary component in crayon manufacturing. Food Packaging Industry: Coating some cheeses to prevent drying and undesirable mold growth. Coating fruits (like apples and citrus) to extend shelf life and enhance shine (must be food-grade). Added to paper and cardboard to create water-resistant properties in food packaging. Cosmetics and Personal Care Industry: As a base in lotions,

Types of Paraffin

Types of Paraffin: Ancient Art and Infinite Variety Understanding the **types of paraffin** is essential, as this versatile substance, primarily composed of saturated hydrocarbons (alkanes), finds a wide range of applications. Existing in various forms, both solid and liquid, paraffin is mainly derived from petroleum and holds a special place across numerous industries due to its unique properties. This comprehensive guide will delve into the various forms, their unique characteristics, and diverse applications of **paraffin types**. 1. What is Paraffin? Exploring the Different Types Definition and Key Properties Paraffin is primarily composed of hydrocarbon molecular chains containing carbon and hydrogen atoms. Depending on the length of these chains, paraffin can exist as a liquid or a solid. Let’s look at the main **types of paraffin** in this regard: Paraffin Wax / Solid Paraffin: The solid form of paraffin, which is **white, odorless, tasteless, and waxy** at room temperature. Its melting point usually ranges from **47 to 64 degrees Celsius**. It’s composed of longer-chain alkanes (approximately C20 to C40). It is **hydrophobic** (repels water) and insoluble in water. It’s a good electrical insulator. It is relatively chemically inert. Liquid Paraffin / Mineral Oil: The liquid form of paraffin, which is **colorless, odorless, tasteless, and transparent**. It’s composed of shorter-chain alkanes than solid paraffin (approximately C15 to C40). Available in “industrial” and highly purified “pharmaceutical/food-grade” forms. 2. History and Origin of Paraffin The discovery and development of paraffin marked a significant turning point in various industries, especially in candle-making and the petroleum industry. Discovery and Naming (Early 19th Century): Karl von Reichenbach: A German chemist, formally discovered and identified **paraffin wax** in 1830. He obtained this substance while studying residues from the distillation of wood tar. Origin of the name “Paraffin”: Reichenbach chose the name “paraffin” from two Latin words: “parum,” meaning “little,” and “affinis,” meaning “affinity” or “inclination” (implying “lack of affinity”). This name was selected due to the substance’s high **non-reactivity** with other chemicals, which is one of its key properties. Commercial Development and Early Applications (Second Half of the 19th Century): James Young: A Scottish chemist, played a crucial role in the commercialization of paraffin production. In the 1850s, he developed processes for extracting paraffin (both liquid and solid) from coal and oil shales, producing it commercially. He even became known as “Young’s Paraffin” due to his work in this field. Revolution in Candle-making: Before paraffin’s discovery, candles were primarily made from animal fat (tallow) or beeswax, which produced a lot of smoke and were expensive. Paraffin wax revolutionized this industry because: Cleaner and More Uniform Burn: Paraffin candles produced less smoke and had a more stable flame. Lower Production Cost: With the development of petroleum refining methods, paraffin production became cheaper than beeswax and animal fat, making candles more accessible to the general public. Other Early Uses: In its early days, paraffin wax was also used in other industries, including as an insulator for telegraph cables, a waterproofing coating for surfaces, and in match production. Industrial Growth and Diverse Applications (20th Century Onwards): With the growth of the petroleum and meatpacking industries (which produced paraffin and stearic acid as by-products), paraffin production peaked in the early 20th century. Advances in refining processes (like vacuum distillation and hydrocracking) improved the quality of paraffin, paving the way for its diverse applications in cosmetics, pharmaceuticals, food, and other industries. Today, **paraffin** has become one of the most widely used materials globally, maintaining its position due to its desirable properties and cost-effectiveness. Understanding the different **types of paraffin** is essential for its proper application across various sectors. 3. Main Types of Paraffin: A Detailed Look Beyond the two main forms (solid and liquid), there are other significant **types of paraffin** or related materials, each with distinct characteristics and applications: Paraffin Wax: The solid paraffin described above. Liquid Paraffin / Mineral Oil: The liquid paraffin described above. Microcrystalline Wax: A type of petroleum derivative similar to paraffin wax, but with a smaller and more irregular crystal structure. It has a higher melting point (around 60 to 93 degrees Celsius) and greater flexibility. Often used in combination with paraffin wax to increase hardness and melting point. Chlorinated Paraffin: Liquid or solid paraffin combined with chlorine. Used to increase flame resistance (flame retardant) and as a plasticizer in specific industries. Petroleum Jelly / Vaseline: A mixture of liquid paraffin and microcrystalline wax with some heavier hydrocarbons. It’s a semi-solid gel primarily used in health and beauty products. 4. Paraffin Production Method: How Different Types of Paraffin Are Made Most commercial **types of paraffin** are derived from crude oil: Crude Oil Distillation: Crude oil is heated in refineries and separated into different petroleum fractions based on their boiling points. Wax Extraction: Heavier petroleum fractions containing paraffinic hydrocarbons (usually from the “lubricating oil” section) are separated. Dewaxing: In this step, oil is separated from the wax. This can be done by cooling the mixture to crystallize the wax, followed by filtration, or by using specific solvents. Refining: The crude wax obtained may contain impurities, color, and odor. To produce purer grades (especially food-grade or pharmaceutical-grade), refining processes such as hydrogenation (reaction with hydrogen), treatment with activated clay, or activated carbon are used to remove unwanted compounds. Other Methods: Paraffin can also be produced synthetically from natural gas (Fischer-Tropsch process) or from coal and oil shale, but production from crude oil remains the most common and economical method for various **types of paraffin**. 5. Uses of Paraffin (Household and Industrial) Due to its chemical and physical properties, various **types of paraffin** are used in a wide range of products and processes: a) Uses of Paraffin Wax (Solid): Candle Making: The most common use of paraffin wax, due to its suitable melting point, clean burn, and ability to hold fragrance and color. Crayons: As a primary component in crayon manufacturing. Food Packaging Industry: Coating some cheeses to prevent drying and undesirable mold growth. Coating fruits (like apples and citrus) to extend shelf life and enhance shine (must be

Introduction to Paraffin Wax and Its Properties

Introduction to Paraffin Wax: Properties and History **Paraffin Wax** is a versatile, soft, and colorless solid derived from petroleum, coal, or oil shale. Known for its waxy texture, **Paraffin Wax** appears in opaque white or milky shades, making it a key material in various industries. At Imex Georgia, we provide high-quality **Paraffin Wax** for applications ranging from candle making to electrical insulation. What is Paraffin Wax? **Paraffin Wax** is a hydrocarbon compound with 20 to 40 carbon atoms, belonging to the alkane family (CnH2n+2). Solid at room temperature, it melts above 37°C into liquid paraffin and boils above 370°C. Its odorless and tasteless nature makes it ideal for diverse uses, including **Paraffin Wax** candles and industrial applications. History of Paraffin Wax Discovered in 1830 by German chemist Carl von Reichenbach, **Paraffin Wax** revolutionized candle making. Unlike tallow fat, it burned cleanly, was cost-effective, and reliable. Early **Paraffin Wax** had a low melting point, but adding stearic acid improved its hardness, expanding its industrial applications in the 20th century. Key Properties of Paraffin Wax **Paraffin Wax** is chemically stable, with saturated bonds that resist reactions. It dissolves in solvents like benzene and ether, has low electrical conductivity, and serves as an excellent insulator for wires and plastics. Its high heat capacity allows **Paraffin Wax** to store significant heat, making it valuable in thermal applications. Why Choose Imex Georgia for Paraffin Wax? Imex Georgia offers premium **Paraffin Wax** sourced from trusted suppliers. Contact us via IMEXGEORGIA.COM to explore our **Paraffin Wax** offerings and request a quote for your needs. © 2025 Imex Georgia. All rights reserved.

Paraffin Production Methods

Paraffin Production Methods: From Petroleum to Purity **Paraffin Production** is a sophisticated process that transforms petroleum derivatives into high-purity paraffin for industrial and commercial use. At Imex Georgia, we source paraffin crafted through advanced **Paraffin Production** techniques to ensure quality for applications like candle making and lubrication. Overview of Paraffin Production **Paraffin Production** begins with petroleum-derived paraffin wax, which contains impurities. To achieve pure paraffin, the material undergoes processing to remove excess oil, resulting in solid or liquid paraffin suitable for various industries. Steps in Paraffin Production Crystallization Process In **Paraffin Production**, impure paraffin wax is heated with chemical solvents like ketones and gradually cooled to crystallize the paraffin, enhancing its purity. Filtration The crystallized paraffin is separated from the solvent stream through filtration, a critical step in **Paraffin Production** to isolate pure paraffin. Distillation Distillation in **Paraffin Production** removes the solvent, allowing it to be reused, while the purified paraffin is prepared for market as solid or liquid forms. Enhancing Paraffin for Industry Adding stearic acid during **Paraffin Production** increases the wax’s hardness, making it suitable for candles and other applications. This process, developed in the early 20th century, revolutionized industries like meat and oil packaging. Contact Imex Georgia for Paraffin Needs Explore our high-quality paraffin products at IMEXGEORGIA.COM. Contact us to learn more about **Paraffin Production** and order premium paraffin for your projects. © 2025 Imex Georgia. All rights reserved.

Applications of Paraffin Uses Wax

Paraffin Uses: Versatile Applications Across Industries **Paraffin Uses** span multiple industries, from candle making to food and cosmetics. Imex Georgia provides high-quality paraffin for diverse **Paraffin Uses**, ensuring performance and reliability for your projects. Key Paraffin Uses in Industry Candle Making with Paraffin One of the primary **Paraffin Uses** is in candle production. Its low melting point allows quick melting and solidification, ideal for creating colorful candles with added pigments. Lubrication and Oils **Paraffin Uses** include producing lubricating oils for bicycle chains and machinery, ensuring smooth operation and durability. Food and Cosmetic Applications Edible-grade paraffin is a key **Paraffin Use** in food coatings for candies, chewing gum, and cheese, as well as in cosmetics as a moisturizing agent alongside Vaseline. Industrial Paraffin **Paraffin Uses** extend to metal casting, stationery (crayons, thermal printer ink), rubber tire protection, paper production, radiotherapy shielding, and wood processing. Why Choose Imex Georgia for Paraffin Uses? Imex Georgia offers premium paraffin tailored for various **Paraffin Uses**. Visit IMEXGEORGIA.COM to explore our paraffin products and request a quote. © 2025 Imex Georgia. All rights reserved.

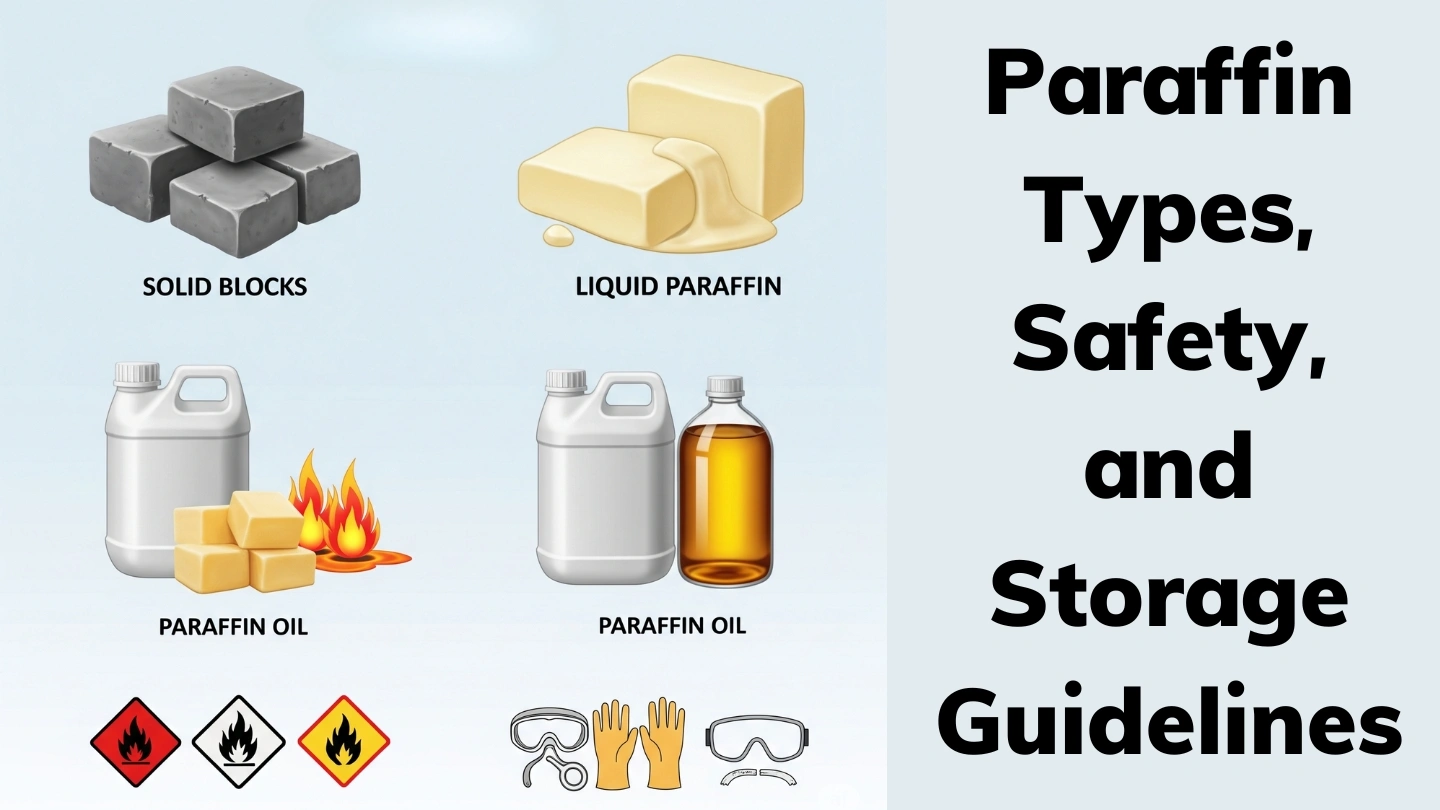

Types, Safety, and Storage of Paraffin

Paraffin Types, Safety, and Storage Guidelines **Paraffin Types** include solid, liquid, and jelly paraffin, each suited for specific industrial and commercial applications. Imex Georgia provides high-quality **Paraffin Types** for candle making, cosmetics, and more, along with safety and storage guidance. Types of Paraffin in the Market **Paraffin Types** include: Solid Paraffin: Available in granular, crystalline, or slab forms, with fat content from 1–18%. High-quality solid paraffin is odorless and clear white. Liquid Paraffin: Used in cosmetics and food industries, often packaged in 20-liter barrels. Jelly Paraffin: Applied in specialized industrial and cosmetic uses. Sanitary, industrial, and candle-making **Paraffin Types** are available at Imex Georgia. Safety Guidelines for Paraffin Types While **Paraffin Types** are non-toxic, prolonged exposure may cause skin or eye irritation and respiratory issues from vapors. Avoid contact with oxidizing materials, as paraffin is stable but can become unstable under excessive heat. Storage Tips for Paraffin Types Store **Paraffin Types** in cool, dry, well-ventilated areas away from heat sources. Use sealed containers to prevent fire hazards from vapors. Solid paraffin is packaged in 25–30 kg bags or 1000 kg bulk bags, while liquid paraffin comes in barrels. Order Paraffin Types from Imex Georgia Contact Imex Georgia via IMEXGEORGIA.COM to source premium **Paraffin Types** for your needs. Request a quote today! © 2025 Imex Georgia. All rights reserved.

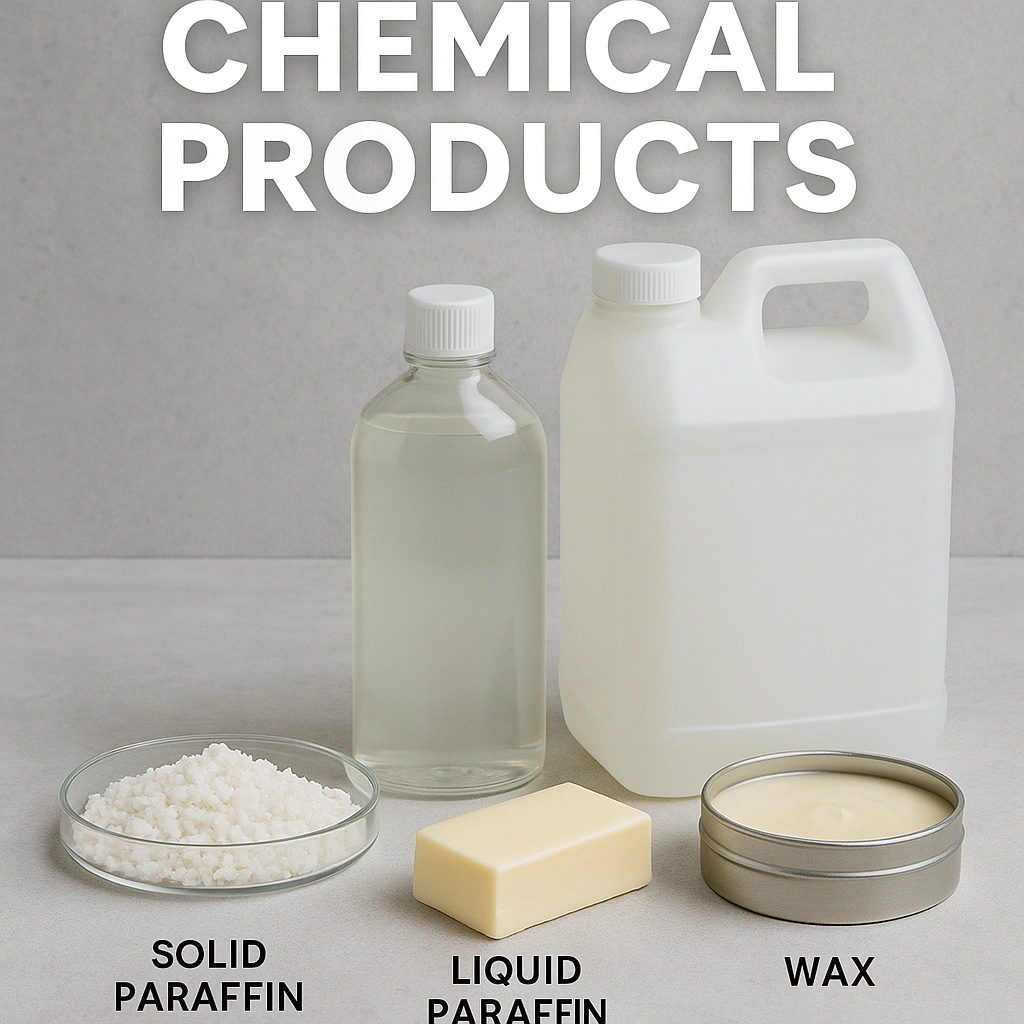

Chemical Products

Chemical Products – Paraffin, Car Care & Industrial Solutions Introduction to Our Chemical Products Imex Georgia delivers high-quality chemical products tailored for various industrial and commercial needs. Our offerings include solid and liquid paraffin, car cleaning chemicals, and versatile wax products. Designed to meet international safety and performance standards, our chemical solutions support diverse sectors. Types of Chemical Products Offered by Imex Georgia Dry Paraffin – Industrial Chemical Solution Our dry paraffin is used in candle making, waterproofing, and packaging. This chemical product ensures long-lasting stability and performance, ideal for industrial-grade applications. Liquid Paraffin – Medical and Cosmetic Use Liquid paraffin from Imex Georgia is a refined chemical product used in pharmaceuticals, personal care, and as a lubricant. It’s known for its purity and smooth consistency, making it a staple in sensitive applications. Car Cleaning Chemical Solutions Our automotive chemical products include detergents, degreasers, and specialized waxes. They remove grime efficiently and protect the vehicle surface, maintaining a clean and professional appearance. Multipurpose Industrial Wax This wax product supports industries such as woodworking, leather treatment, and food packaging. As a flexible chemical solution, it offers protection, shine, and durability in multiple applications. Advantages of Our Chemical Products All our products are quality-checked and compliant with international safety standards. Benefits include long shelf life, high efficiency, and cost-effectiveness. Whether for industrial, automotive, or commercial use, Imex Georgia provides reliable chemical solutions. Industries Benefiting from Our Chemical Products We proudly serve automotive service providers, manufacturers, cosmetic brands, and construction sectors. The adaptability of our chemical solutions ensures clients receive effective results across all use cases. Sustainable and Safe Chemical Practices Our commitment to eco-friendly processes drives innovation in our chemical production. We use recyclable materials and safe formulations that reduce environmental impact without compromising performance. Why Imex Georgia Is a Trusted Chemical Supplier Years of experience, global logistics capabilities, and strict quality assurance make Imex Georgia a leading name in chemical product supply. From paraffin to car cleaning chemicals, we offer dependable solutions that customers trust. Contact Us for Premium Chemical Product Solutions If you’re looking for top-tier chemical products such as paraffin, car cleaning solutions, and waxes, reach out to Imex Georgia. Let’s collaborate to boost your operations with premium chemical solutions.