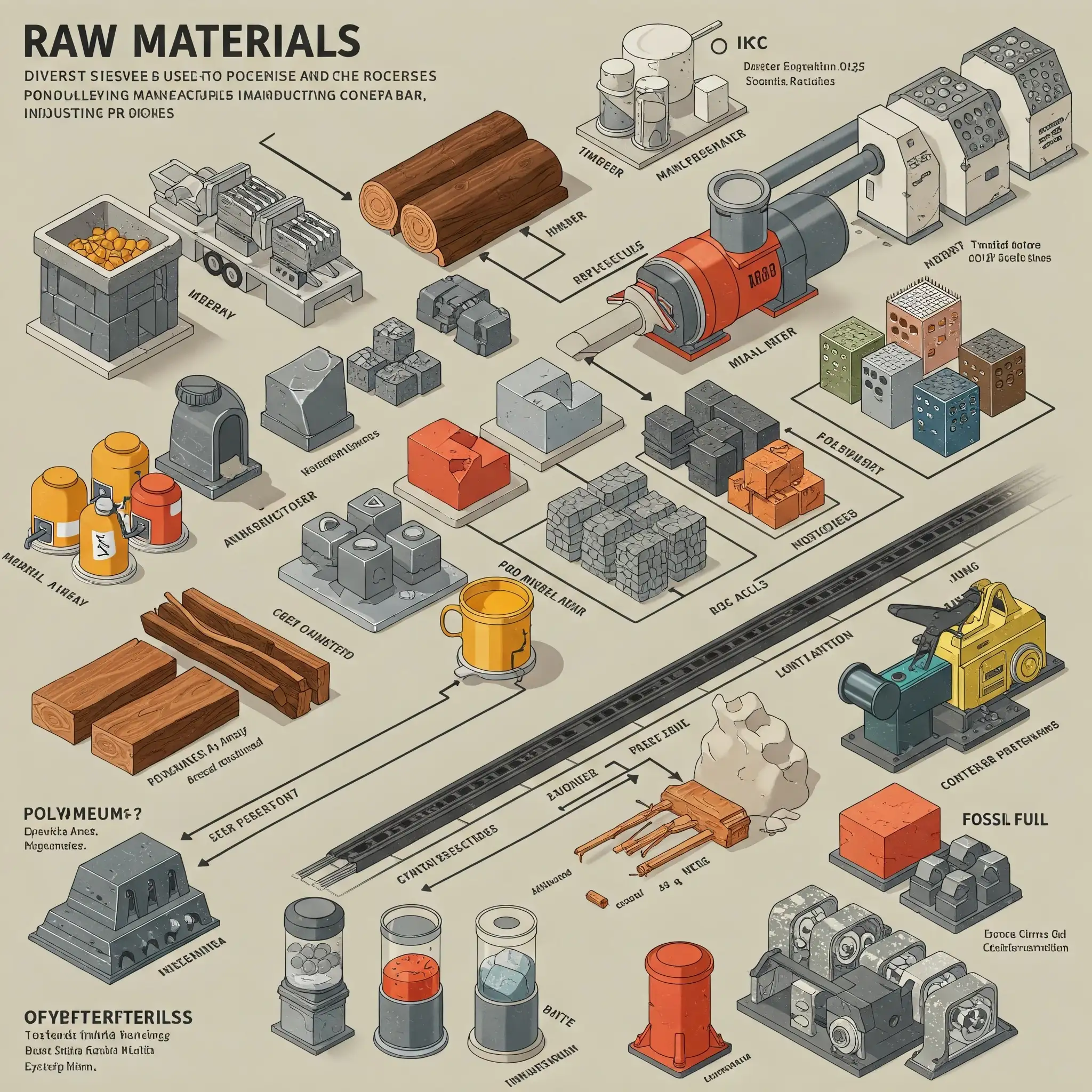

Raw Materials: The Foundation of Sustainable and Efficient Production At Imex Georgia, we understand that the strength of any finished product lies in the quality of its raw materials. We are a leading supplier of essential raw materials, providing the foundational components that drive various manufacturing and production processes across industries. Our commitment is to deliver consistent, high-quality raw materials that empower your business to produce superior products, maintain operational efficiency, and meet the demands of a dynamic market. Why Quality Raw Materials are Non-Negotiable for Your Business In the intricate world of manufacturing, the choice of raw materials directly impacts product quality, production costs, and overall market competitiveness. Inferior raw materials can lead to product defects, increased waste, costly production delays, and ultimately, damage to your brand reputation. Conversely, investing in premium raw materials ensures: Consistent Product Quality: High-grade raw materials result in high-quality finished goods, reducing variability and ensuring customer satisfaction. Optimized Production Efficiency: Reliable raw materials minimize machine downtime, reduce rework, and streamline your manufacturing processes. Cost-Effectiveness: While quality raw materials may sometimes have a higher initial cost, they reduce waste, energy consumption, and the need for costly defect rectifications in the long run. Enhanced Product Performance: Superior raw materials contribute to the durability, strength, and overall performance characteristics of your end products. Regulatory Compliance: Sourcing certified raw materials helps ensure your products meet industry standards and regulatory requirements. Imex Georgia is dedicated to being your reliable partner in sourcing the raw materials you need to achieve these critical objectives, empowering your manufacturing operations to thrive. Our Core Raw Material Offerings: Powering Key Industries Imex Georgia specializes in providing raw materials crucial for high-demand product categories. Our focus ensures deep expertise and consistent supply chains for these vital components. Raw Materials for Single-Use Disposable Products Production The market for single-use disposable products is vast and constantly evolving, driven by convenience, hygiene, and specific industry needs. From food packaging to medical supplies, the production of these items relies heavily on a steady supply of specific raw materials. Imex Georgia is a trusted provider of high-quality raw materials for single-use disposable products, supporting manufacturers in creating safe, durable, and cost-effective solutions. Polypropylene (PP) Granules Polypropylene (PP) is a cornerstone raw material for many single-use items due to its excellent clarity, high melting point, chemical resistance, and ease of processing. We supply various grades of PP granules suitable for: Disposable Containers and Lids: Used for food packaging, such as yogurt cups, deli containers, and microwaveable trays. Plastic Cutlery: Spoons, forks, and knives for food service. Syringes and Medical Devices: Certain grades of PP are crucial for medical-grade disposables due to their inertness and sterilization capabilities. Bottle Caps and Closures: Providing secure seals for beverages and other liquids. Our PP granules ensure consistent melt flow, impact strength, and clarity, which are essential for high-volume production of disposable items. Polystyrene (PS) Granules Polystyrene (PS) is another widely used raw material for disposable products, especially for its rigidity, clarity, and insulation properties. We offer PS granules in both general-purpose (GPPS) and high-impact (HIPS) grades for applications like: Disposable Drinking Cups: Both clear and foam cups (expanded polystyrene). Disposable Plates and Bowls: Often made from HIPS for durability. Food Trays: For meat, poultry, and produce packaging. CD/DVD Cases: Though less common now, PS remains important for specific rigid packaging. Our PS granules provide the necessary rigidity and surface finish for demanding disposable product applications. Polyethylene Terephthalate (PET) Pellets PET is highly valued for its barrier properties, strength, and transparency, making it a primary raw material for various single-use beverage and food containers: Beverage Bottles: Water bottles, soft drink bottles, and juice containers. Food Jars: Peanut butter jars, condiment bottles. Clamshell Containers: For baked goods and fresh produce. We ensure our PET pellets meet high standards for clarity, impact resistance, and barrier performance, critical for food and beverage packaging. Biodegradable and Compostable Polymers (Upon Request) Recognizing the growing demand for sustainable solutions, we are also able to source and supply raw materials for biodegradable and compostable single-use products, such as PLA (Polylactic Acid) and PBAT (Polybutylene Adipate Terephthalate). These options help manufacturers meet eco-friendly objectives and respond to evolving consumer preferences. Our expertise in sourcing these diverse raw materials ensures that manufacturers of single-use disposable products have access to the best components for their specific needs, supporting both conventional and environmentally conscious production lines. Raw Materials for Waste Bag Production Waste bags, or garbage bags, are ubiquitous in households, commercial establishments, and industrial settings. Their effectiveness hinges on their strength, tear resistance, and puncture resistance. Imex Georgia supplies the primary raw materials necessary for producing high-quality, durable, and reliable waste bags suitable for various applications. Low-Density Polyethylene (LDPE) Granules LDPE is the most common raw material for flexible packaging, including many types of waste bags. It offers excellent flexibility, tear resistance, and a good balance of strength and stretch. Our LDPE granules are ideal for: Standard Household Waste Bags: Providing flexibility and moderate strength. Liners for Bins and Containers: Conformable and resistant to minor punctures. Recycling Bags: Often clear or translucent for easy content identification. We ensure our LDPE provides consistent melt flow and film properties for efficient extrusion and durable bag production. High-Density Polyethylene (HDPE) Granules HDPE is known for its superior strength, rigidity, and puncture resistance compared to LDPE, making it an excellent raw material for heavy-duty waste bags. Our HDPE granules are perfect for: Heavy-Duty Waste Bags: For construction debris, industrial waste, or large volumes of household trash. Star-Sealed or Gusseted Bags: Where extra strength at seams is required. Medical Waste Bags: Often requiring higher puncture resistance and chemical inertness. Thin-Gauge Bags: HDPE’s strength allows for thinner films, reducing material usage while maintaining performance. Our HDPE granules are optimized for film extrusion, ensuring maximum strength and tear resistance for demanding waste bag applications. Linear Low-Density Polyethylene (LLDPE) Granules LLDPE combines the best properties of both LDPE and HDPE, offering superior tensile strength, puncture resistance, and tear resistance while maintaining good flexibility.